Reimagining cold-chain reliability for remote healthcare

Designing a context-appropriate vaccine coolbox that keeps doses between 2°C–8°C without electricity, reducing preventable vaccine loss in low-resource settings.

Product Design

Human-Centered Research

Prototyping

User Research

CAD

Solidworks

Keyshot

Adobe Suite

Recognition for real-world impact

Awards and press coverage following the project’s development.

Understanding the Challenge

While exploring global health challenges, I focused on the issue of vaccine wastage in low-resource settings where maintaining the 2°C–8°C cold chain can be unreliable or impossible. After speaking with organisations such as PATH and Médecins Sans Frontières, it became clear that existing cool boxes were either too fragile, too reliant on ice packs, or not suited for long, unpredictable journeys. This project set out to design a context-appropriate solution that addressed the realities of remote clinics and field workers, where durability, simplicity, and thermal performance are non-negotiable.

My role

Designer & Researcher

I led the end-to-end process, from field research and problem definition to physical prototyping, testing insulation materials, designing the form factor, and validating the cooling method.

How I contributed

- A fully designed vaccine cool box concept built for all environments.

- Prototypes testing insulation materials and the vacuum-powered cooling system.

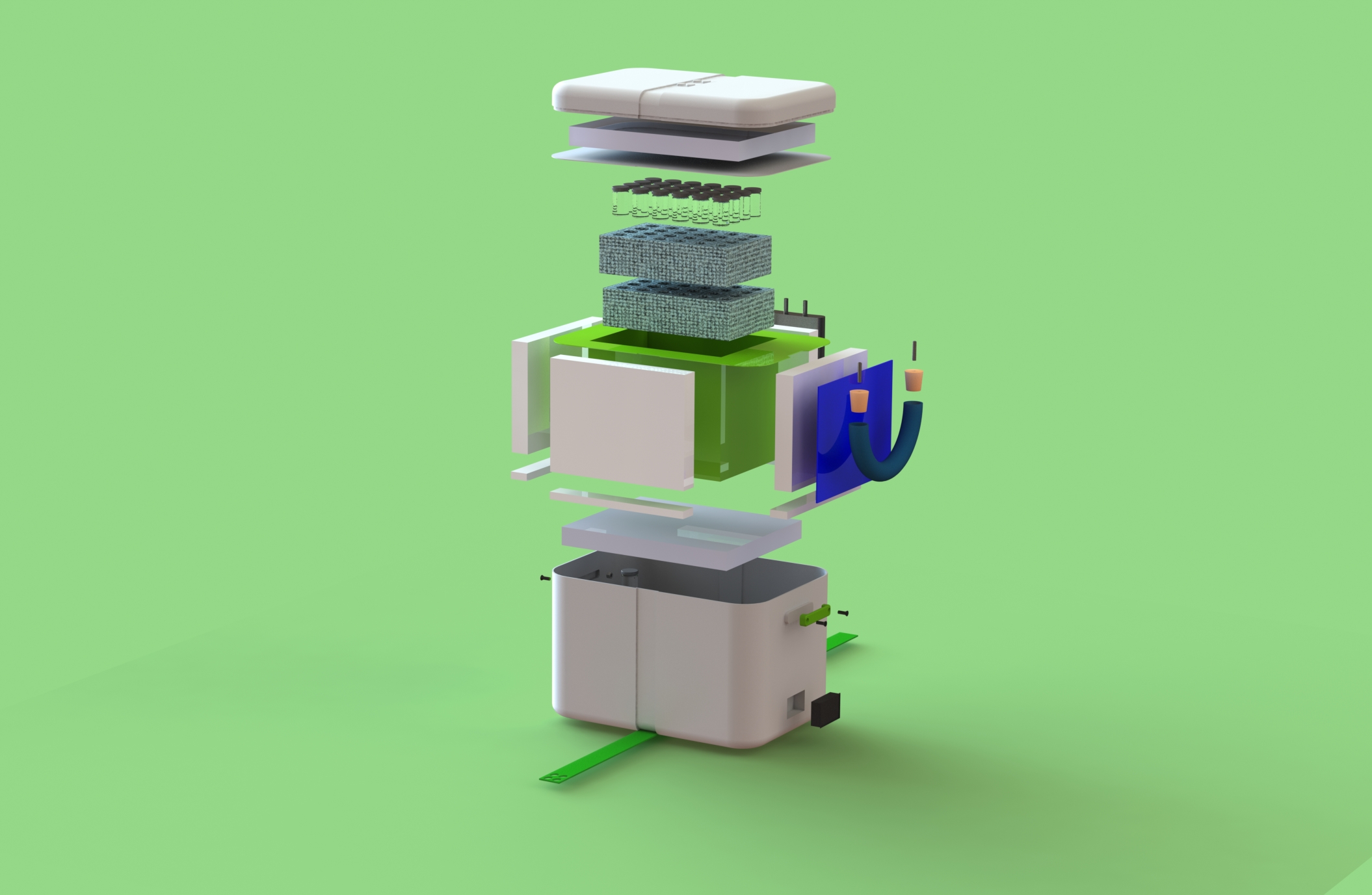

- A CAD model and physical form prototype guided by manufacturability constraints.

- Branding and a context-appropriate visual identity.

What I delivered

- Conducted primary research with global health organisations.

- Mapped user journeys and benchmarked existing products.

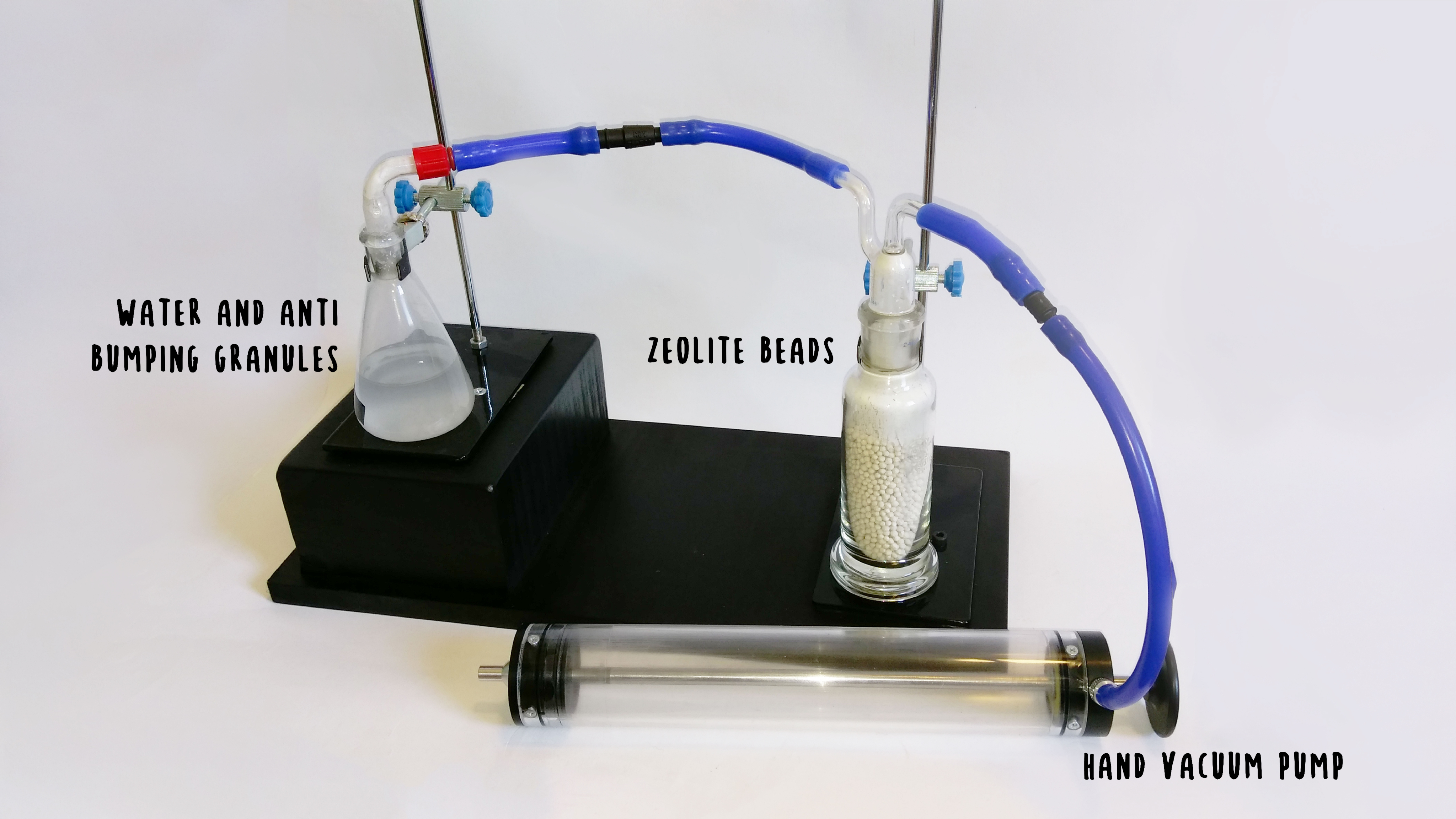

- Prototyped insulation tests and cooling mechanism trials.

- Developed form, usability features, and manufacturable casing design.

- Created and evaluated colour and brand direction through user feedback.

Designed for the realities of last-mile delivery

Vaccines aren’t transported in controlled laboratory environments. They’re carried across long distances, harsh climates, and unpredictable conditions. The cool box needed to be simple, durable, and able to maintain temperature without relying on ice packs or electricity. By designing around real users; health workers, volunteers, and community teams, I focused on reliability, efficiency, and ease of use, so the system performs wherever it’s needed most.

Reliable cooling without electricity

The coolbox uses vacuum-driven evaporative cooling to keep vaccines within the safe 2°C–8°C range, without ice packs or power. By lowering the air pressure around a small volume of water, the system forces it to boil at room temperature. As the water evaporates, it pulls heat from its surroundings, steadily cooling the internal chamber.

Built for tough environments

Rotomoulded casing, simplified components, and intuitive interactions ensure the cool box withstands travel, handling, and unpredictable conditions.

More capacity, less waste

By removing ice packs, the internal volume increases, supporting more vials per journey and reducing overall wastage.

Cold-chain reliability redefined

Sustainable and safe

No toxic refrigerants, no special disposal required, just simple, dependable materials.

More doses delivered per journey

Eliminating ice packs frees up storage space, increasing vial capacity without increasing the load.

No freezing risks

No ice packs means vaccines stay safely between 2°C–8°C, eliminating one of the most common causes of wastage.

Reducing waste, saving lives

Fewer spoiled vials means more successful vaccinations, safer communities, and better use of limited resources.

Built for remote travel

With no power requirements and multi-day temperature stability, the cool box supports long, difficult routes.

Easy to operate with minimal training

The cooling system is straightforward to activate and maintain, supporting teams who may not have technical training.

How it all came together

A showcase of the brand and website redesign in action.

More work worth exploring

From digital products to brand experiences, a curated selection of my work.

UX/UI

Accessibility

Prototyping

Designing for smarter hiring decisions

Making complex talent insights simple and human.

UX/UI

User Research

Prototyping

Redefining the operator experience

Designing intuitive machine interfaces to improve safety and efficiency.

UX/UI

Branding

Web Design

Empowering young voices through design

Brand and digital redesign focused on clarity and trust.

See all projects

Reimagining cold-chain reliability for remote healthcare

Designing a context-appropriate vaccine coolbox that keeps doses between 2°C–8°C without electricity, reducing preventable vaccine loss in low-resource settings.

Product Design

Human-Centered Research

Prototyping

User Research

CAD

Solidworks

Keyshot

Adobe Suite

Recognition for real-world impact

Awards and press coverage following the project’s development.

Understanding the Challenge

While exploring global health challenges, I focused on the issue of vaccine wastage in low-resource settings where maintaining the 2°C–8°C cold chain can be unreliable or impossible. After speaking with organisations such as PATH and Médecins Sans Frontières, it became clear that existing cool boxes were either too fragile, too reliant on ice packs, or not suited for long, unpredictable journeys. This project set out to design a context-appropriate solution that addressed the realities of remote clinics and field workers, where durability, simplicity, and thermal performance are non-negotiable.

My role

Designer & Researcher

I led the end-to-end process, from field research and problem definition to physical prototyping, testing insulation materials, designing the form factor, and validating the cooling method.

How I contributed

- A fully designed vaccine cool box concept built for all environments.

- Prototypes testing insulation materials and the vacuum-powered cooling system.

- A CAD model and physical form prototype guided by manufacturability constraints.

- Branding and a context-appropriate visual identity.

What I delivered

- Conducted primary research with global health organisations.

- Mapped user journeys and benchmarked existing products.

- Prototyped insulation tests and cooling mechanism trials.

- Developed form, usability features, and manufacturable casing design.

- Created and evaluated colour and brand direction through user feedback.

Designed for the realities of last-mile delivery

Vaccines aren’t transported in controlled laboratory environments. They’re carried across long distances, harsh climates, and unpredictable conditions. The cool box needed to be simple, durable, and able to maintain temperature without relying on ice packs or electricity. By designing around real users; health workers, volunteers, and community teams, I focused on reliability, efficiency, and ease of use, so the system performs wherever it’s needed most.

Reliable cooling without electricity

The coolbox uses vacuum-driven evaporative cooling to keep vaccines within the safe 2°C–8°C range, without ice packs or power. By lowering the air pressure around a small volume of water, the system forces it to boil at room temperature. As the water evaporates, it pulls heat from its surroundings, steadily cooling the internal chamber.

Built for tough environments

Rotomoulded casing, simplified components, and intuitive interactions ensure the cool box withstands travel, handling, and unpredictable conditions.

More capacity, less waste

By removing ice packs, the internal volume increases, supporting more vials per journey and reducing overall wastage.

Cold-chain reliability redefined

More doses delivered per journey

Eliminating ice packs frees up storage space, increasing vial capacity without increasing the load.

Sustainable and safe

No toxic refrigerants, no special disposal required, just simple, dependable materials.

No freezing risks

No ice packs means vaccines stay safely between 2°C–8°C, eliminating one of the most common causes of wastage.

Reducing waste, saving lives

Fewer spoiled vials means more successful vaccinations, safer communities, and better use of limited resources.

Built for remote travel

With no power requirements and multi-day temperature stability, the cool box supports long, difficult routes.

Easy to operate with minimal training

The cooling system is straightforward to activate and maintain, supporting teams who may not have technical training.

How it all came together

A showcase of the brand and website redesign in action.

More work worth exploring

From digital products to brand experiences, a curated selection of my work.

UX/UI

Accessibility

Prototyping

Designing for smarter hiring decisions

Making complex talent insights simple and human.

UX/UI

User Research

Prototyping

Redefining the operator experience

Designing intuitive machine interfaces to improve safety and efficiency.

UX/UI

Branding

Web Design

Empowering young voices through design

Brand and digital redesign focused on clarity and trust.

See all projects

Reimagining cold-chain reliability for remote healthcare

Designing a context-appropriate vaccine coolbox that keeps doses between 2°C–8°C without electricity, reducing preventable vaccine loss in low-resource settings.

Product Design

Human-Centered Research

Prototyping

User Research

CAD

Solidworks

Keyshot

Adobe Suite

Recognition for real-world impact

Awards and press coverage following the project’s development.

Understanding the Challenge

While exploring global health challenges, I focused on the issue of vaccine wastage in low-resource settings where maintaining the 2°C–8°C cold chain can be unreliable or impossible. After speaking with organisations such as PATH and Médecins Sans Frontières, it became clear that existing cool boxes were either too fragile, too reliant on ice packs, or not suited for long, unpredictable journeys. This project set out to design a context-appropriate solution that addressed the realities of remote clinics and field workers, where durability, simplicity, and thermal performance are non-negotiable.

My role

Designer & Researcher

I led the end-to-end process, from field research and problem definition to physical prototyping, testing insulation materials, designing the form factor, and validating the cooling method.

How I contributed

- A fully designed vaccine cool box concept built for all environments.

- Prototypes testing insulation materials and the vacuum-powered cooling system.

- A CAD model and physical form prototype guided by manufacturability constraints.

- Branding and a context-appropriate visual identity.

What I delivered

- Conducted primary research with global health organisations.

- Mapped user journeys and benchmarked existing products.

- Prototyped insulation tests and cooling mechanism trials.

- Developed form, usability features, and manufacturable casing design.

- Created and evaluated colour and brand direction through user feedback.

Designed for the realities of last-mile delivery

Vaccines aren’t transported in controlled laboratory environments. They’re carried across long distances, harsh climates, and unpredictable conditions. The cool box needed to be simple, durable, and able to maintain temperature without relying on ice packs or electricity. By designing around real users; health workers, volunteers, and community teams, I focused on reliability, efficiency, and ease of use, so the system performs wherever it’s needed most.

Reliable cooling without electricity

The coolbox uses vacuum-driven evaporative cooling to keep vaccines within the safe 2°C–8°C range, without ice packs or power. By lowering the air pressure around a small volume of water, the system forces it to boil at room temperature. As the water evaporates, it pulls heat from its surroundings, steadily cooling the internal chamber.

Built for tough environments

Rotomoulded casing, simplified components, and intuitive interactions ensure the cool box withstands travel, handling, and unpredictable conditions.

More capacity, less waste

By removing ice packs, the internal volume increases, supporting more vials per journey and reducing overall wastage.

Cold-chain reliability redefined

More doses delivered per journey

Eliminating ice packs frees up storage space, increasing vial capacity without increasing the load.

Sustainable and safe

No toxic refrigerants, no special disposal required, just simple, dependable materials.

No freezing risks

No ice packs means vaccines stay safely between 2°C–8°C, eliminating one of the most common causes of wastage.

Reducing waste, saving lives

Fewer spoiled vials means more successful vaccinations, safer communities, and better use of limited resources.

Built for remote travel

With no power requirements and multi-day temperature stability, the cool box supports long, difficult routes.

Easy to operate with minimal training

The cooling system is straightforward to activate and maintain, supporting teams who may not have technical training.

How it all came together

From prototype to production; turning research, requirements, and constraints into an interface operators can trust.

More work worth exploring

From digital products to brand experiences, a curated selection of my work.

UX/UI

Accessibility

Prototyping

Designing for smarter hiring decisions

Making complex talent insights simple and human.

UX/UI

Branding

Web Design

Helping a youth charity show up with confidence

Brand and digital redesign focused on clarity and trust.

UX/UI

User Research

Prototyping

Redefining the operator experience

Brand and digital redesign focused on clarity and trust.

See all projects